Mick Moor - Silo & Tank Design & Installation

|

I started this business back in 1985, aimed primarily at the livestock sector of the agricultural industry. Situated on the edge of The Peak District, I am ideally placed to serve the whole of Great Britain, and even beyond.

Originally, we carried out fabrication and installation of our own steelwork as well as assembly and erection of items supplied by others. My first job; to move and extend this hay barn

|

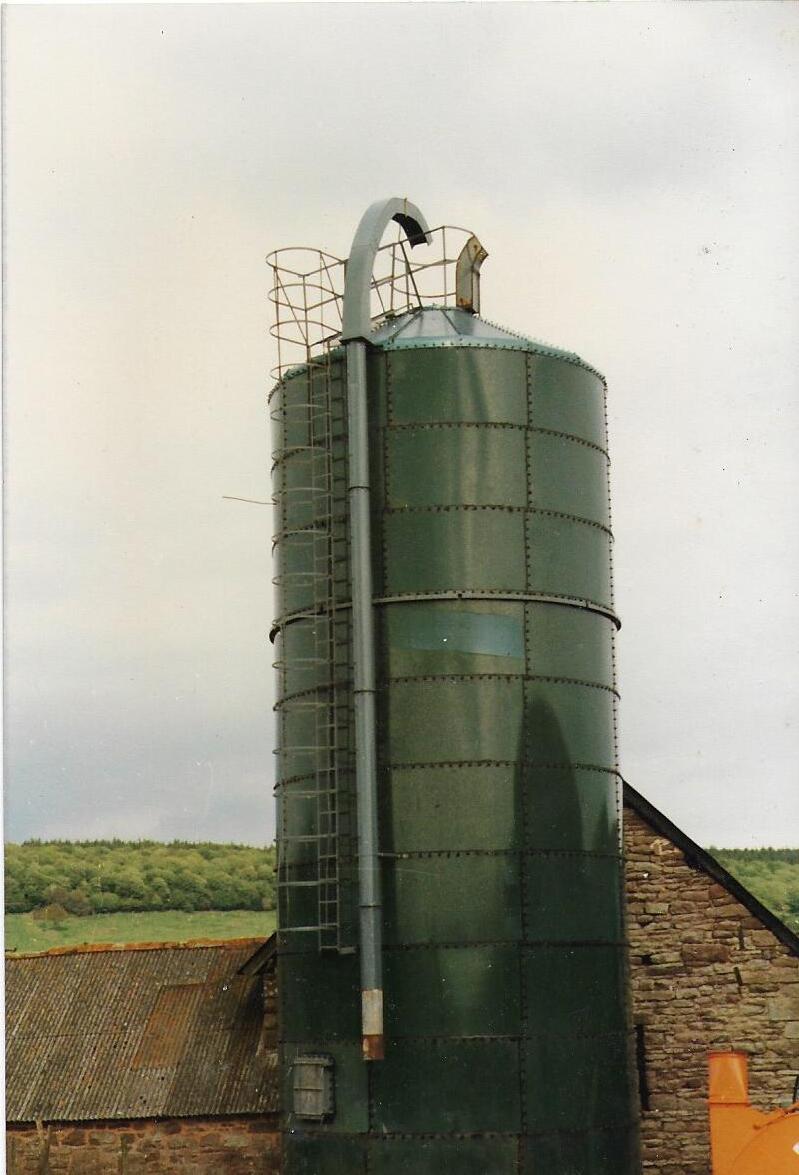

The 1st Silo I helped Build

|

Gradually the business has evolved, still concentrating on the livestock sector, surviving the falsely predicted epidemic of BSE, the real epidemics of foot and mouth disease and bovine TB, and catastrophic drops in the wholesale price of milk and pork, even the financial crisis of 2008! Experience is mainly in bulk storage and handling, of liquid or granular material such as cattle and pig slurry, grain and other feedstuffs along with liquids like water, molasses, leachate and digestate.

My specialist knowledge of sealed moist grain silos and slurry stores has taken me throughout Great Britain, France, Sweden, Ireland, Belgium, and Germany. I have a wealth of experience in planning and installation of tanks, silos, and hoppers, as well as dismantling silo and slurry equipment and re-erecting it on alternative sites. I also carry out related site work, including planning and execution of craned lifts, slinging, banking, cherry picker operation etc. Recently the developing green energy industry has resulted in an increase in enquiries for digesters and stores to hold and treat digestate, leading to quite a few orders.

Now, due to advancing years, the business is reduced to just myself, using this practical experience to advise, supervise, and supply the most suitable equipment for your intended use. Although I still carry out site work myself, I also use a reliable sub-contractor, who has worked with me throughout for tank and silo construction.

My extensive contacts in engineering and the rest of industry mean that I can source many items that are not readily available, including stainless steel and PVC fabrications, improved versions and copies of obsolete parts.

Continuing the theme of storage, I also sell Armorgard products, particularly because they willingly advise on the most suitable safe, secure store for chemicals, tools, and machinery. Https://www.armorgard.co.uk/markets/agriculture

My specialist knowledge of sealed moist grain silos and slurry stores has taken me throughout Great Britain, France, Sweden, Ireland, Belgium, and Germany. I have a wealth of experience in planning and installation of tanks, silos, and hoppers, as well as dismantling silo and slurry equipment and re-erecting it on alternative sites. I also carry out related site work, including planning and execution of craned lifts, slinging, banking, cherry picker operation etc. Recently the developing green energy industry has resulted in an increase in enquiries for digesters and stores to hold and treat digestate, leading to quite a few orders.

Now, due to advancing years, the business is reduced to just myself, using this practical experience to advise, supervise, and supply the most suitable equipment for your intended use. Although I still carry out site work myself, I also use a reliable sub-contractor, who has worked with me throughout for tank and silo construction.

My extensive contacts in engineering and the rest of industry mean that I can source many items that are not readily available, including stainless steel and PVC fabrications, improved versions and copies of obsolete parts.

Continuing the theme of storage, I also sell Armorgard products, particularly because they willingly advise on the most suitable safe, secure store for chemicals, tools, and machinery. Https://www.armorgard.co.uk/markets/agriculture

My customer filling my first slurry store