Slurry Store Inspection and Repairs

All things deteriorate with age, and silos and tanks are no exception. Regular inspection and maintenance will enable you to get the maximum life out of this expensive fixed equipment. A repair as soon as damage is noticed is cheaper than leaving things until repair becomes essential.

Furthermore, your insurers or the Environment Agency (or your local equivalent) often ask for assurance that your slurry store or moist grain silo is still capable of doing the job it was designed for.

Never enter a slurry store without checking for poisonous gases. Hydrogen sulphide smells of rotten eggs, but in high concentrations dulls your sense of smell. It also dissolves in slurry, like the gas in fizzy pop. Stir it up by walking in the liquid, and the gas is released. As well as poisoning one person this way, tragically, often the rescuer is killed as well.

STOP, THINK SLURRY GAS!!

Furthermore, your insurers or the Environment Agency (or your local equivalent) often ask for assurance that your slurry store or moist grain silo is still capable of doing the job it was designed for.

Never enter a slurry store without checking for poisonous gases. Hydrogen sulphide smells of rotten eggs, but in high concentrations dulls your sense of smell. It also dissolves in slurry, like the gas in fizzy pop. Stir it up by walking in the liquid, and the gas is released. As well as poisoning one person this way, tragically, often the rescuer is killed as well.

STOP, THINK SLURRY GAS!!

My 35+ years’ experience building, dismantling, and re-erecting this type of store should qualify me to inspect them, as may be required periodically by such bodies as insurers, land agents and the Environment Agency. A comprehensive written report will provide information on over-all condition, with recommended repairs and their likely cost. Regular inspection can also spot damage while it is relatively cheap to repair.

For an inspection, the store must be completely empty. Getting me to take a sheet out of the second ring is a good way to increase ventilation to allow cleaning a store out ready for inspection.

A thorough inspection starts by walking round the tank, noting any damage and its position. Any possible causes of early failure will be noted and recorded. The outlet will be checked, to make sure it is compliant with regulations. The inspection platform and access ladder will also be checked to make sure they are in good condition. Inside, every sheet, seam and bolt head is checked and damage recorded; the tank will be checked for level and circularity. If either of these is outside the tolerances given, failure is imminent.

A detailed report will be written, which should satisfy the Environment Agency, and/or your insurers, or a prospective purchaser, with recommendations for necessary repairs. View an example here

For an inspection, the store must be completely empty. Getting me to take a sheet out of the second ring is a good way to increase ventilation to allow cleaning a store out ready for inspection.

A thorough inspection starts by walking round the tank, noting any damage and its position. Any possible causes of early failure will be noted and recorded. The outlet will be checked, to make sure it is compliant with regulations. The inspection platform and access ladder will also be checked to make sure they are in good condition. Inside, every sheet, seam and bolt head is checked and damage recorded; the tank will be checked for level and circularity. If either of these is outside the tolerances given, failure is imminent.

A detailed report will be written, which should satisfy the Environment Agency, and/or your insurers, or a prospective purchaser, with recommendations for necessary repairs. View an example here

After some 20 years, the plastic cap covering the bolt head will deteriorate due to the effects of sunlight. Replacement is a simple but important maintenance task.

The sample report gives more details of what an inspection shows. Though not mentioned in the report, evidence of subsidence is always looked for, since this can result in catastrophic failure of a tank.

Sometimes the customer opts for a cheaper verbal report and then just has the job done.

Sometimes the customer opts for a cheaper verbal report and then just has the job done.

|

A new outlet and PVC filler pipe fitted to a re-conditioned store.

|

Inside the store; some of the repairs are just visible.

|

Some sheets, like these polyester coated ones, are badly corroded on the inside, and the only possible repair is replacement. The manufacturer has long since ceased production, and as the rest of the tank was good, it was worth making copies in stainless steel.

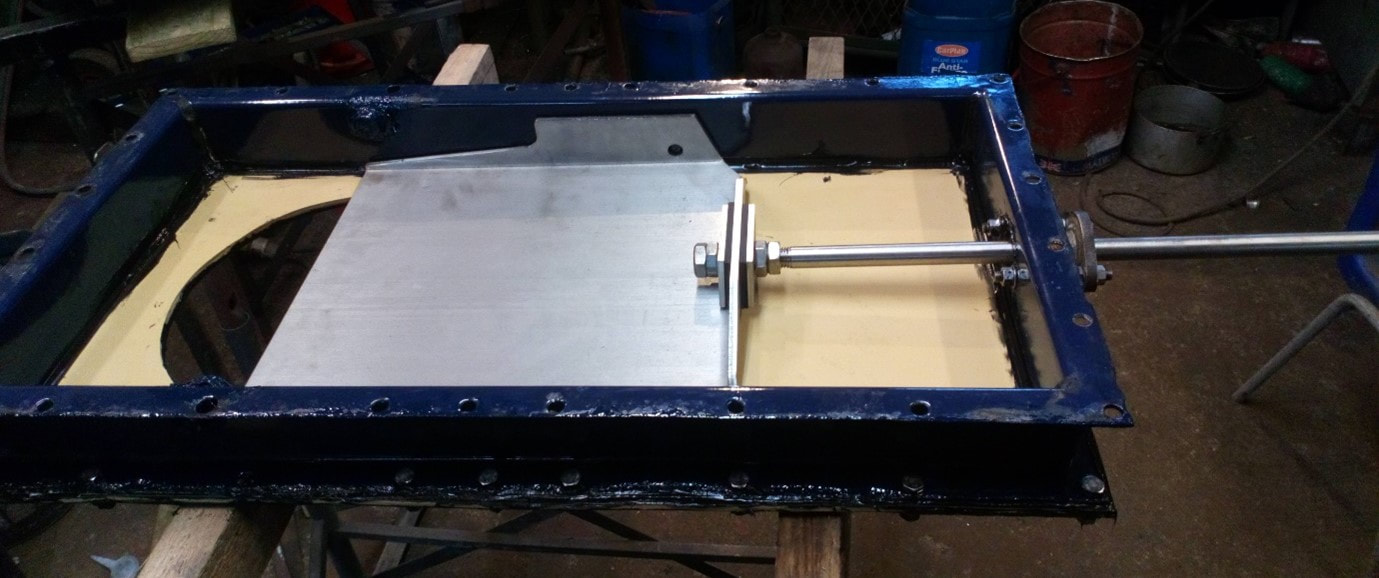

The sluice gate often fails, usually requiring urgent repair, whether it fails open or, less seriously, shut. I offer emergency help for this. Harvestore are the make most likely to fail in this way, due to the slide being made from enameled steel, which corrodes if the coating gets chipped. I hold a stock of repair pieces, some specially made to improve on the original design.

A stainless steel slide, replacement rod with nuts washers and stem gland, and a new face seal should get this sluice operating safely again.

An alternative solution is to block the sluice with concrete and fit a new double valved outlet to the side of the store. I favour PVC inside the tank, as galvanizing corrodes surprisingly quickly, particularly if the store is emptied regularly. If made with PVC it can be tailored to dip into the old sluice depression for better emptying.

An alternative solution is to block the sluice with concrete and fit a new double valved outlet to the side of the store. I favour PVC inside the tank, as galvanizing corrodes surprisingly quickly, particularly if the store is emptied regularly. If made with PVC it can be tailored to dip into the old sluice depression for better emptying.

We have produced some unusual outlets, all to meet the customer’s requirements, such as this which empties from a sump formed in the centre.

Jetters, used to direct the slurry and help break up crust, seem to need regular replacement. Alternately wet with slurry, then exposed to air, the metal parts corrode quickly. It is best to replace the whole unit. Bauer couplings to connect the hose, with stainless steel clamps, are usually in stock. I can supply Jetters with brackets to suit any make of tank, including Storth, Permastore, Harvestore, A O Smith, Malgar, Boythorpe, Alfa Laval and Gascoigne and even Simplex.

Sometimes to reduce smell and froth, the pump delivers the liquid at or below surface level. A length of lay-flat, will achieve this, but a non-return valve must also be fitted in the pipeline to stop the liquid siphoning out of the store.

The old sluice removed and a 250 mm pipe pushed into the old outlet and surrounded with concrete allows the complete replacement of the old sluicegate with a new double valved 12” sluice gate assembly.

Two 8” valves in tandem to attach via an adaptor plate on to an old Harvestore flange to replace an old double valve assembly.

Through the wall mixers operate in severe conditions. A new propellor, both bearings and shaft bring this stirrer up to new condition once again. I have parts for both Storth and Malgar. I have also repaired various mixers by NC and Eisele.

Of course, I can supply a full range of slurry mixing equipment, advising on the most suitable for your particular situation.

A recent electric mixer installation which included a manway in the bottom ring of a digestate store.

A recent electric mixer installation which included a manway in the bottom ring of a digestate store.

Whatever problem your slurry is giving you, I am sure I can work out a cost-effective solution.